Your partner around induction heating and vacuum brazing systems

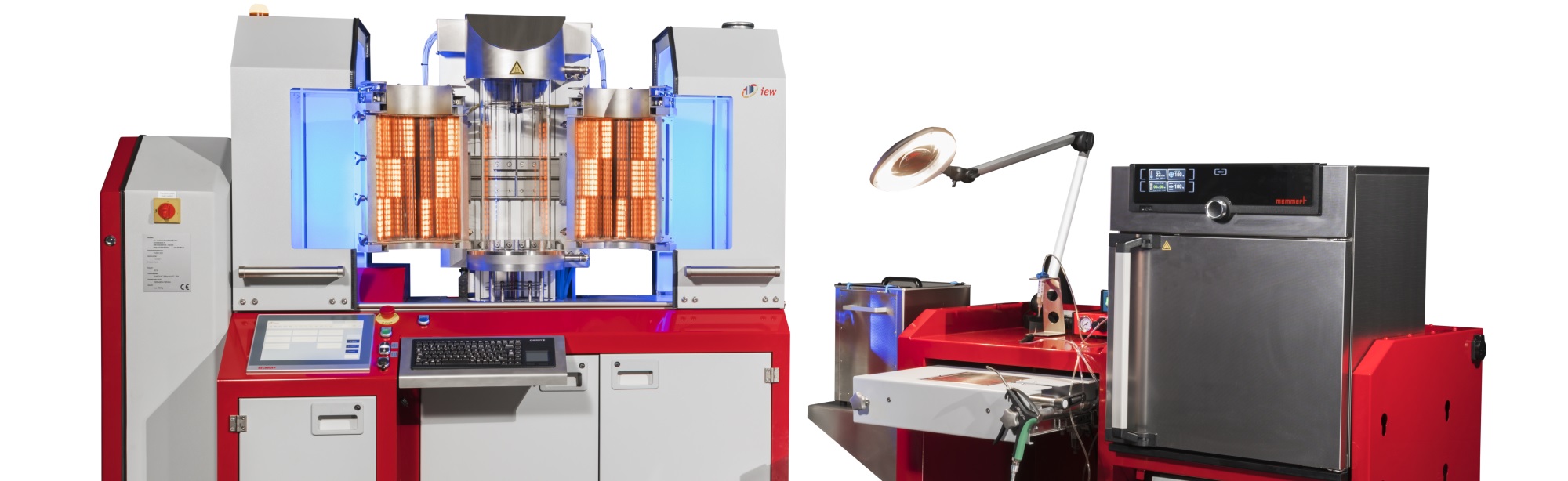

Available for Sale: Nearly New Medium Frequency System with 80 kW Output

We currently offer a nearly new medium frequency induction system with 80 kW power for sale. The unit is in excellent condition and available at short notice.

Interested parties are welcome to contact us directly.

Newest technical article in the Diamond Business:

Diamond Business

Induction heating systems by IEW, medium and high frequency for precise thermal processes

IEW Induktive Erwärmungsanlagen GmbH has been designing and building induction heating systems for industrial metal processing since 1996. What sets us apart is the mix of deep process know how, accurate temperature control, and robust machines. We focus on real production goals, cycle time, quality, repeatability, not on chance.

What you can expect from us

- Accurate temperature control, PLC sequence control with recipe management and data capture delivers repeatable results

- Everyday efficiency, fast heat up, precise energy input, less oxidation and less rework

- Clean processes, no open flame, stable conditions for part quality and workplace safety

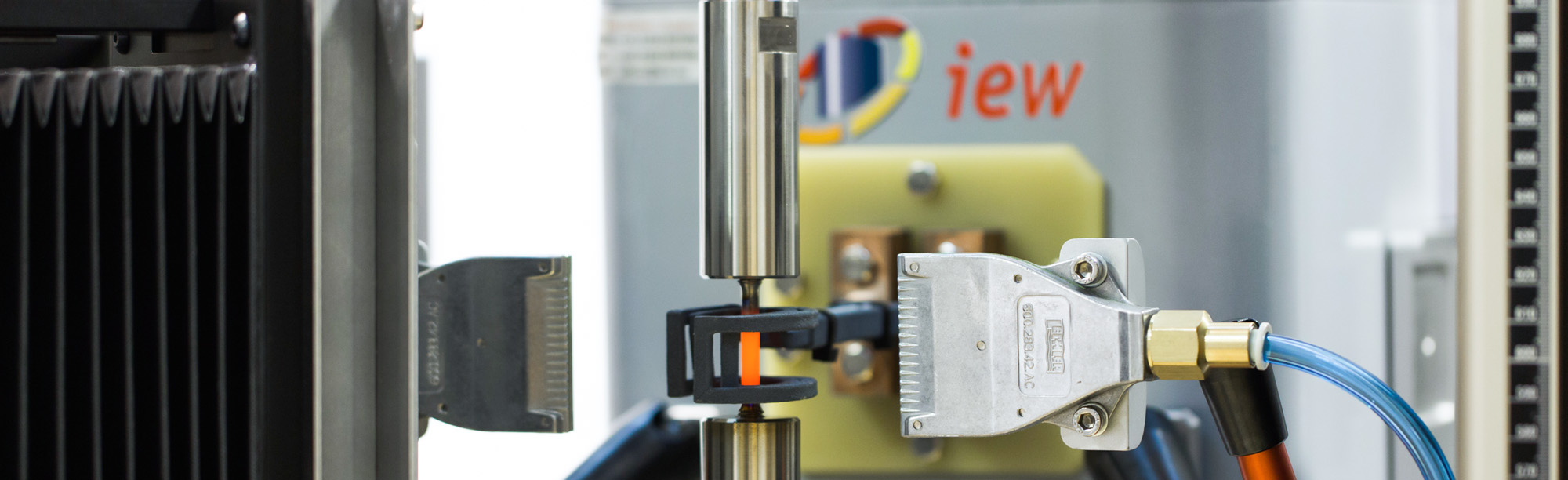

- Adaptability, inductors and frequencies matched to part, geometry, and required penetration depth

- Scalability, from manual workstations to automated production systems with integrated cooling

Solutions and systems

We manufacture induction heating systems and induction generators. We also supply complete solutions for brazing, hardening, annealing and shrink fitting. Depending on your task, we deliver stand alone units or fully integrated systems, for example induction heating with a manual workstation, cooling units for system recooling, workholding, benches and racking. Another focus is vacuum brazing systems for high strength, clean joints without discoloration.

Typical applications from daily production

- Induction brazing of assemblies made of steel, brass, copper, and aluminum

- Induction hardening of defined surface zones such as shafts, gears, and edges

- Annealing to reduce residual stresses or to tailor the microstructure

- Shrink fitting, precise joining and release of press fits

- Use in science and test labs with reproducible heating

Materials expertise

Induction heating is suitable for all electrically conductive materials. That includes ferrous alloys, stainless steel, copper, brass, and aluminum. We support you with inductor design, frequency selection, and a stable process window until the parameters run reliably on your line.

Industries we serve

Our customers come from automotive, toolmaking, and mechanical engineering, as well as research institutes and universities. Together we build projects that work on the shop floor and make economic sense.

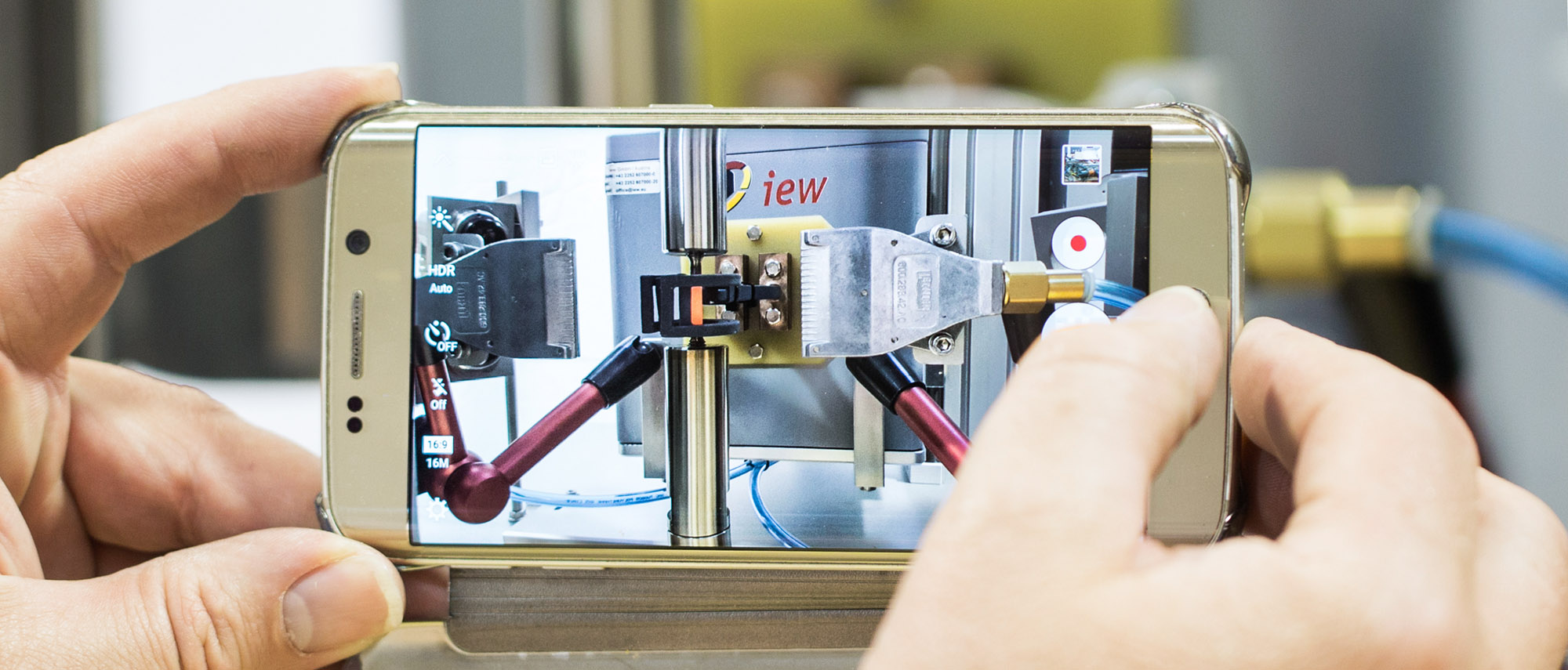

Control, documentation, and service

We are known for temperature control. Our PLC sequence controls drive the heating process with precision. Options include data acquisition, quality documentation, recipe management, and remote access. We support you with commissioning, training, maintenance, and spare parts over the long term.

How we get to the result

- Understand the task, part, material, geometry, target temperatures, and cycle times

- Design the process, inductor, power, frequency, cooling, temperature measurement

- Run samples, find parameters, document and verify them

- Integrate, manual workstation or automation, safety and CE

- Support, training, service, continuous optimization in production

FAQ

What advantages does induction offer compared to flame or furnace

Induction heats targeted and fast. Energy use drops, oxidation decreases, rework goes down. Process safety increases because the heat is exactly where it needs to act.

Which frequency ranges do you use

We implement medium and high frequency, depending on part geometry and required penetration depth. The design is always based on your specific application.

Which materials can be heated inductively

All electrically conductive materials, for example steel, stainless steel, copper, brass, and aluminum. We select inductor geometry and process parameters to match your workpiece.

Do you deliver complete systems

Yes. System, inductor, cooling, workholding, and quality assurance come from one source. This creates stable processes without interface issues.

Do you support validation and documentation

Yes. We provide process data and parameter lists, and on request measurement and test concepts for series approvals.

Talk to us, we will show on your specific part what the right induction solution looks like and how to run it economically.

Products

- 2 HF-output (kW)

- 70 - 450 kHz

- 450 x 150 x 650 mm

- 230 x 180 x 300 mm

- 3 HF-output (kW)

- 70 - 450 kHz

- 450 x 150 x 650 mm

- 230 x 180 x 300 mm

- 5 HF-output (kW)

- 70 - 450 kHz

- 450 x 150 x 650 mm

- 230 x 180 x 300 mm

- 8 HF-output (kW)

- 70 - 450 kHz

- 450 x 150 x 650 mm

- 230 x 230 x 400 mm

- 10 HF-output (kW)

- 70 - 450 kHz

- 450 x 150 x 650 mm

- 230 x 230 x 400 mm

Unsere Anwendungen

Free application analysis

In our laboratory we develop and test the optimal solution for your application.

We have many years of experience and extensive technical know-how in the field of induction heating.

Our equipment and systems are custom-designed to meet each customer’s specific requirements and ensure maximum efficiency and process reliability.

As a result, our equipment and systems offer a short payback period thanks to their efficiency and high process stability.

Our equipment and systems integrate seamlessly into existing production processes, ensuring efficient and smooth operation within your manufacturing environment.

Together with our clients, we optimize the use of our equipment and systems to improve process efficiency and increase overall productivity.