Your partner around induction heating systems

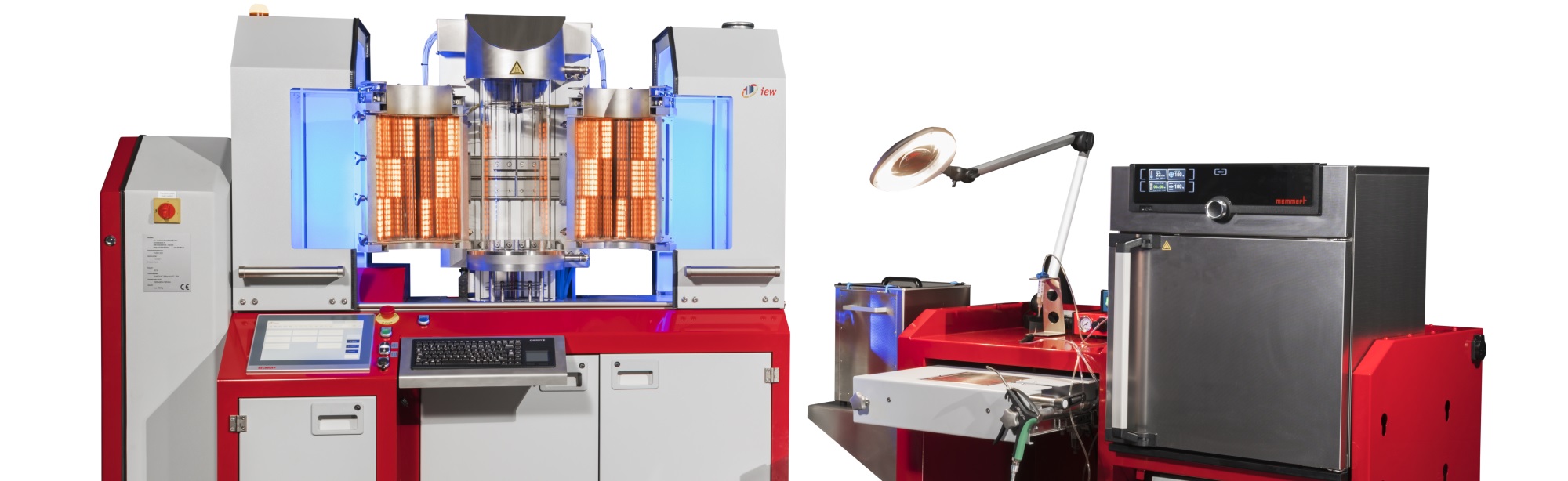

Development and production of medium and high-frequency Induction Heating Systems for Soldering and Brazing, Annealing, Shrink Fitting, Hardening, and Scientific and Testing Applications

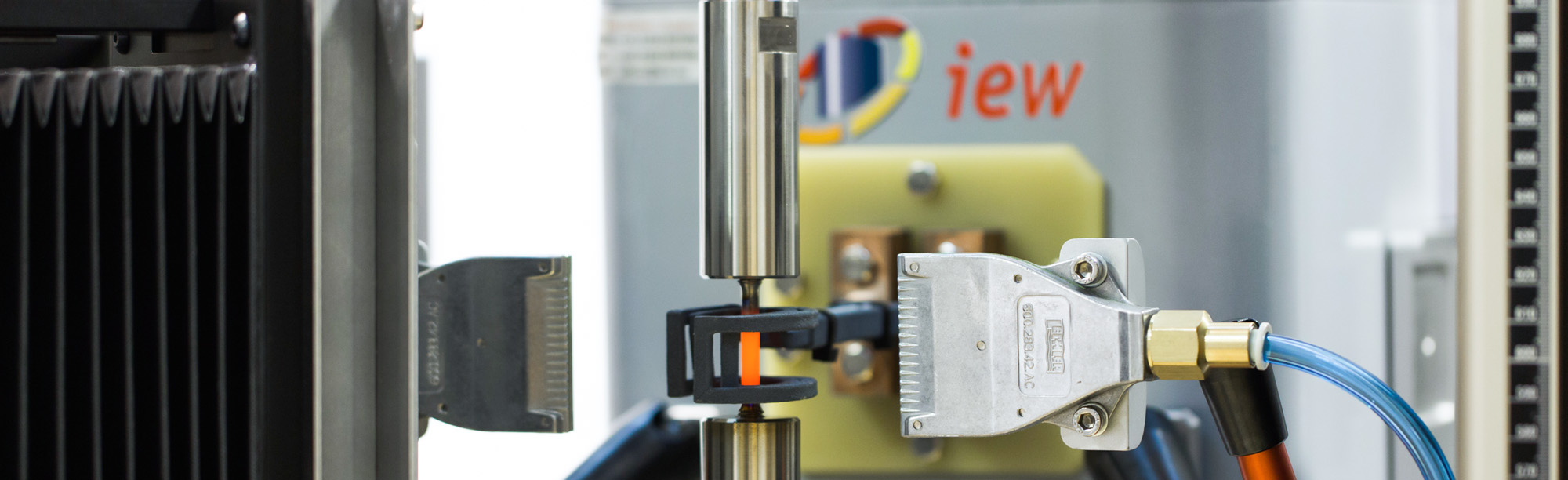

Handling induction heating and induction systems requires years of experience and extensive know-how.

We are a manufacturer of induction systems specializing in heat treatment with induction heating systems and custom solutions for complete customer-specific systems. Since 1996, we have been developing and building equipment and systems for inductive heating. We have made a name for ourselves in the field of temperature control and offer small PLC sequence controls for precisely controlled heating processes. Our customers include globally operating industrial companies from the automotive industry, as well as companies from the tool, machine building, and research sectors, and universities.

Inductive heating can be used wherever metals need to be processed by heat. It is suitable for workpieces made of iron, stainless steel, copper, brass, aluminum, and all other electrically conductive materials.

In addition to the development, production, and sale of induction generators/induction heating systems in general, iew also offers soldering systems, hardening systems, embossing systems, as well as customized complete systems, e.g., induction heating systems with manual workstations, cooling systems for cooling the induction systems, table and shelf systems, etc.

In the meantime, vacuum brazing systems have also become one of our core areas!

Products

- 2 HF-output (kW)

- 70 - 450 kHz

- 450 x 150 x 650 mm

- 230 x 180 x 300 mm

- 3 HF-output (kW)

- 70 - 450 kHz

- 450 x 150 x 650 mm

- 230 x 180 x 300 mm

- 5 HF-output (kW)

- 70 - 450 kHz

- 450 x 150 x 650 mm

- 230 x 180 x 300 mm

- 8 HF-output (kW)

- 70 - 450 kHz

- 450 x 150 x 650 mm

- 230 x 230 x 400 mm

- 10 HF-output (kW)

- 70 - 450 kHz

- 450 x 150 x 650 mm

- 230 x 230 x 400 mm

Unsere Anwendungen

Free application analysis

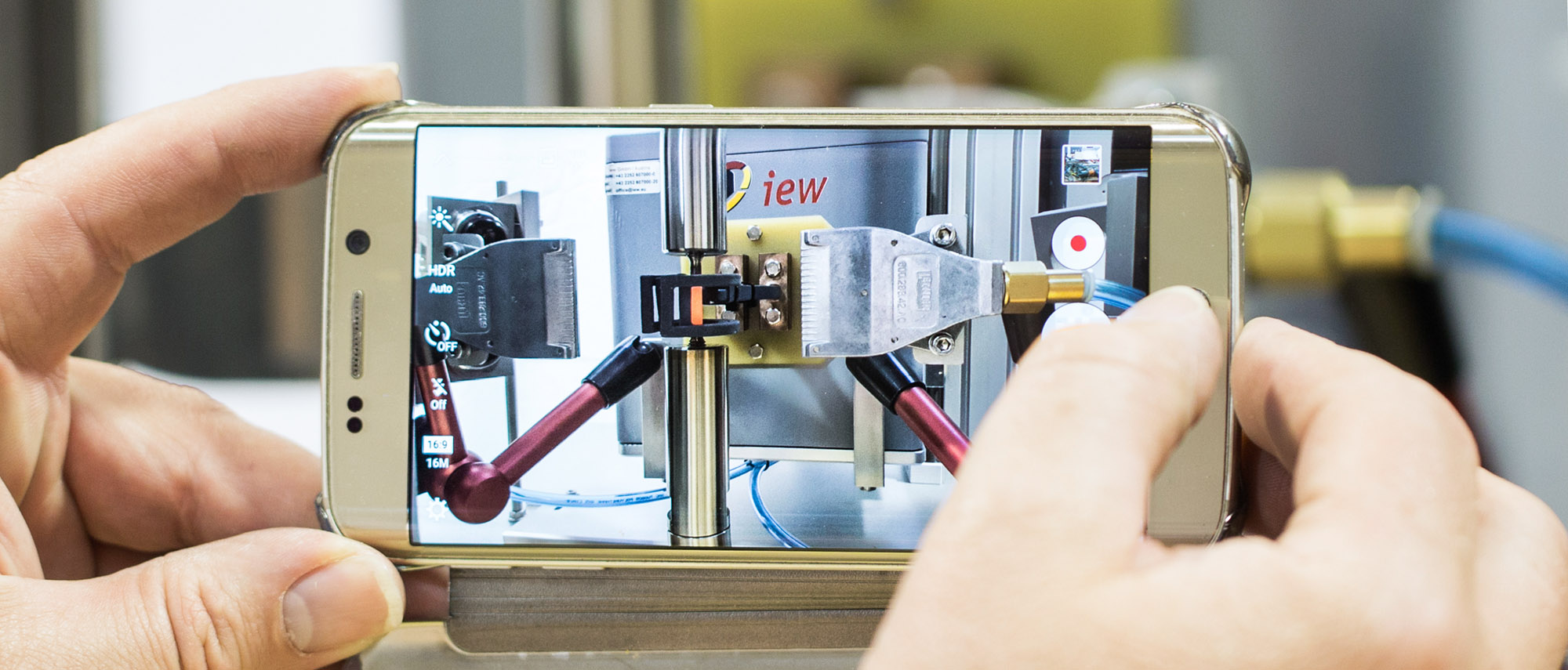

In our laboratory we develop and test the optimal solution for your application.

- We have many years of experience and extensive know-how.

- Our equipment and systems are customized to meet the customer's needs.

- As a result, our equipment and systems have a short payback period.

- Our equipment and systems fit seamlessly into the production process.

- Together with the client, we optimize the use of our equipment and systems.