IHU110/2 (Induction Hardening Unit – 1 x TTH10 10kW)

Härteanlagen

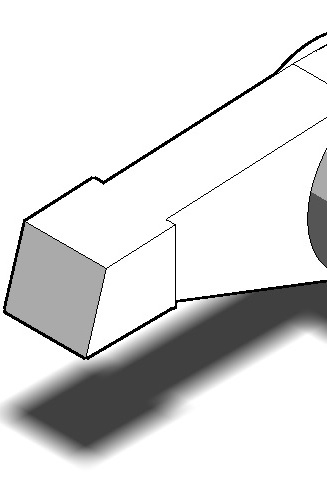

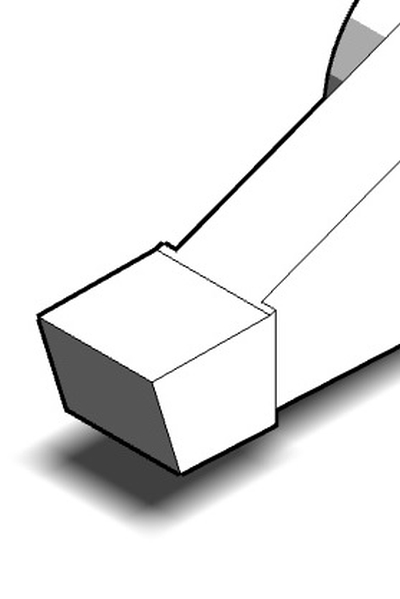

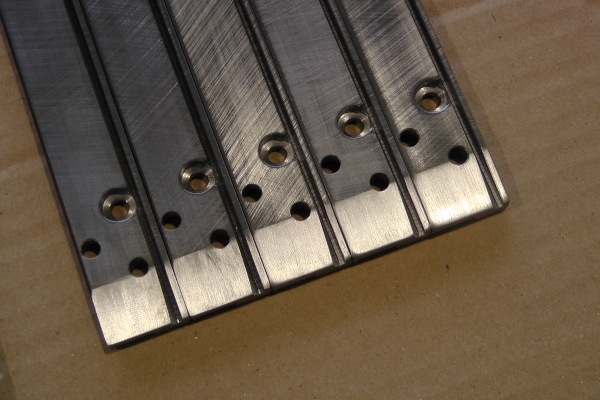

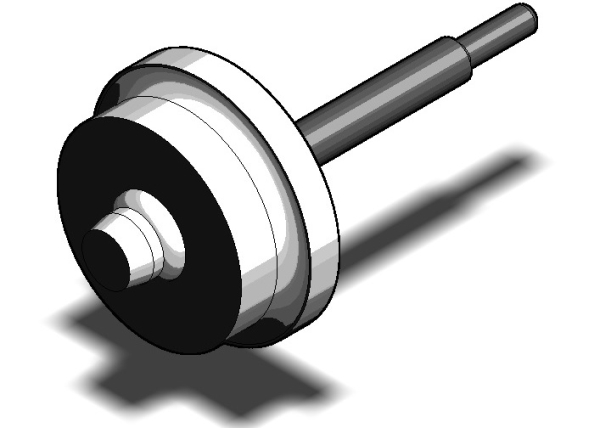

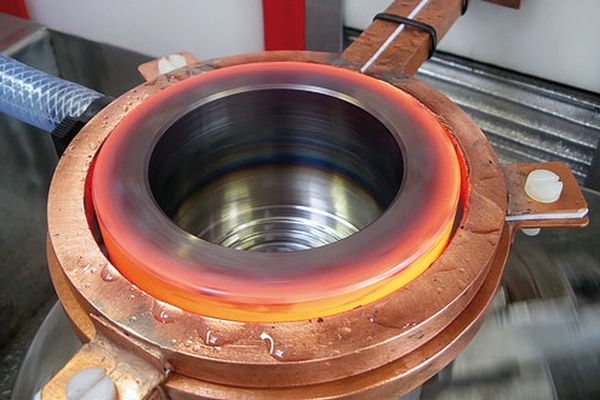

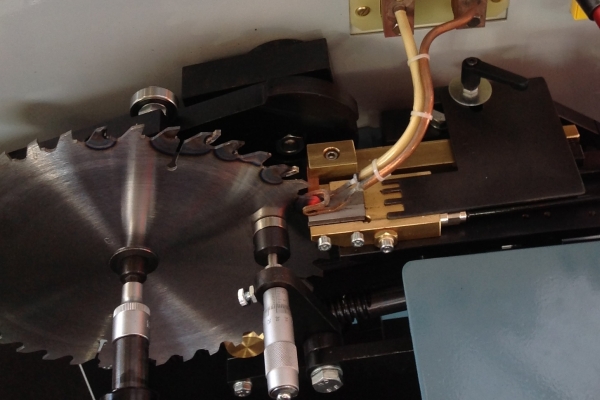

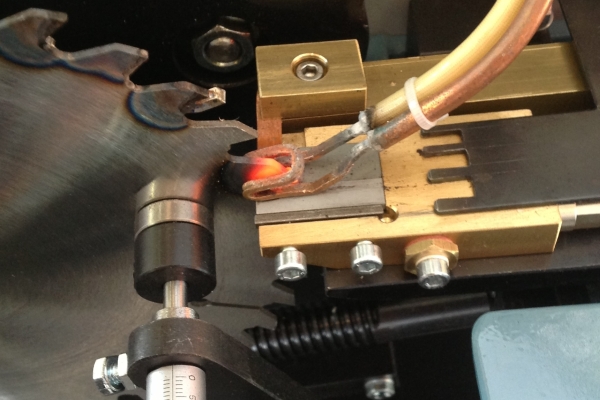

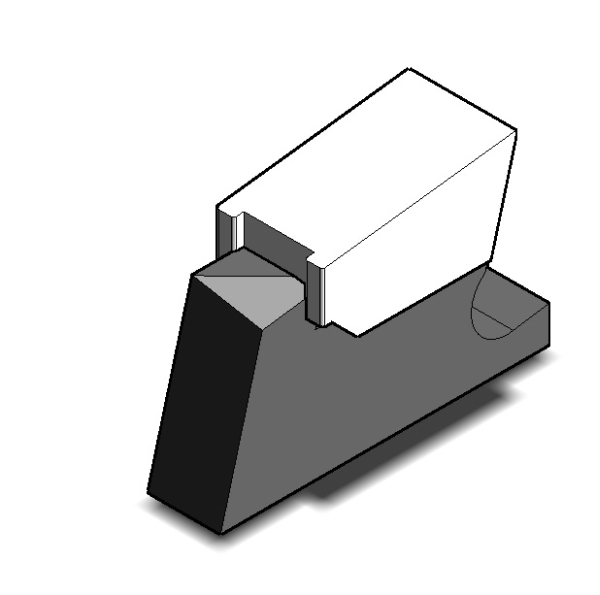

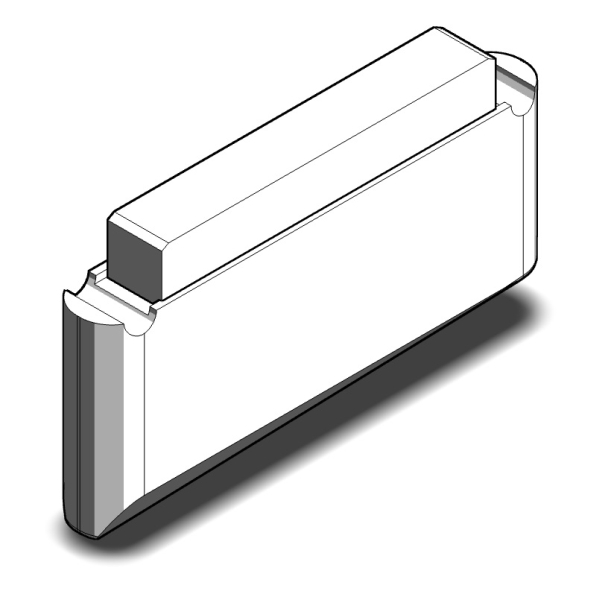

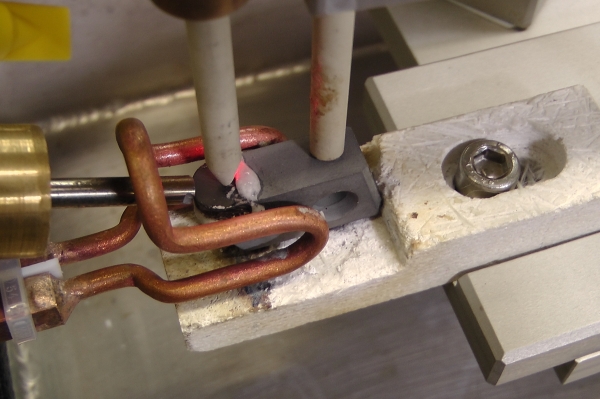

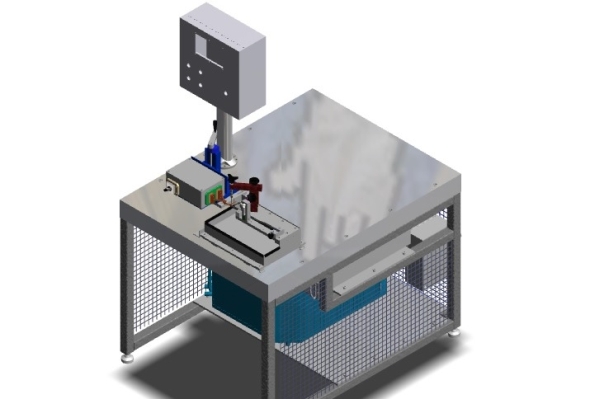

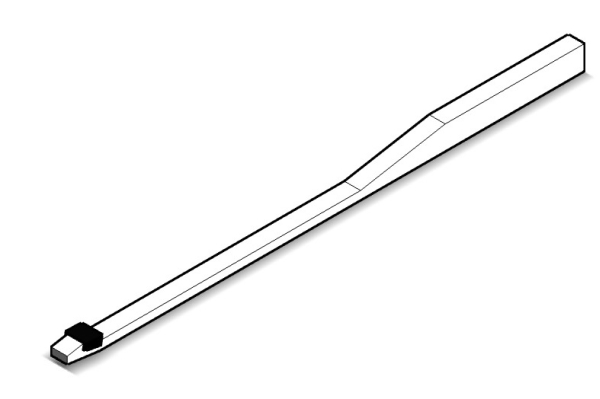

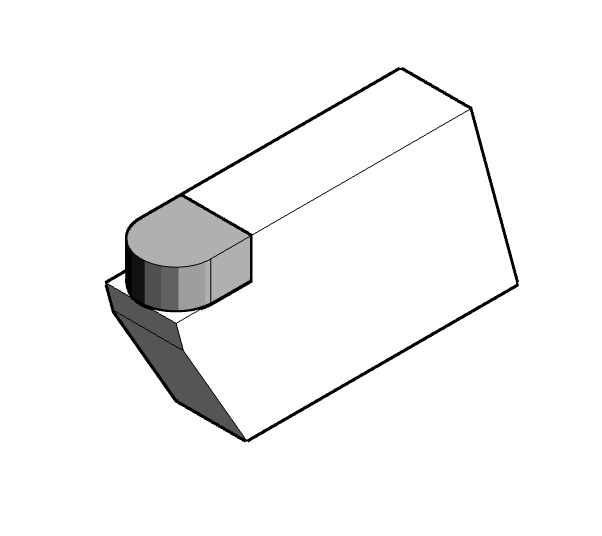

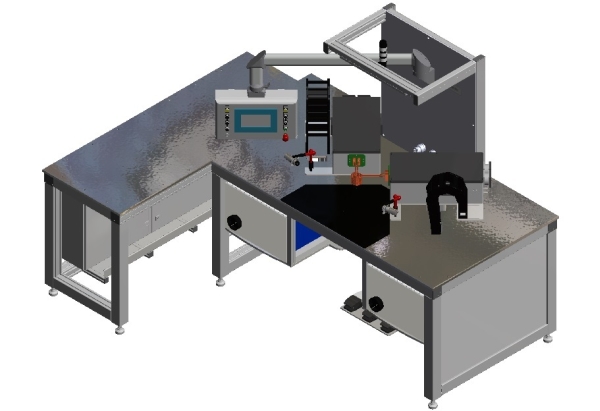

This small work place was constructed for the hardening of rocker arms for aircraft and motor sport engines. The zone to be hardened is approximately 10mm x 10mm.

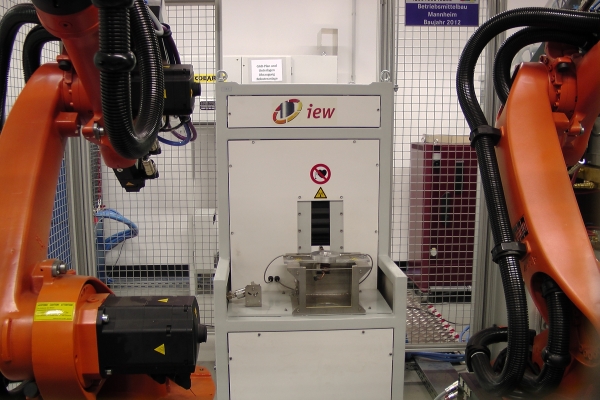

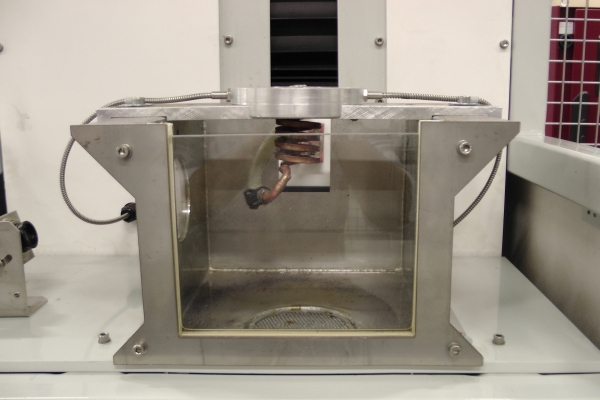

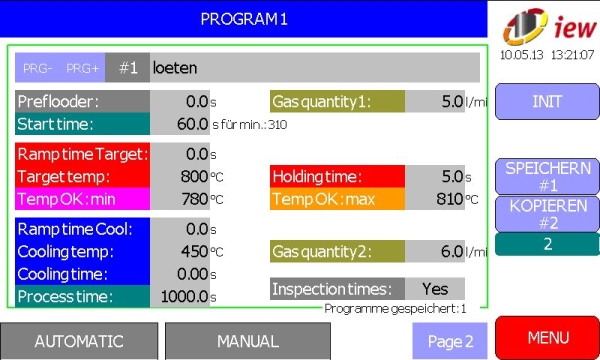

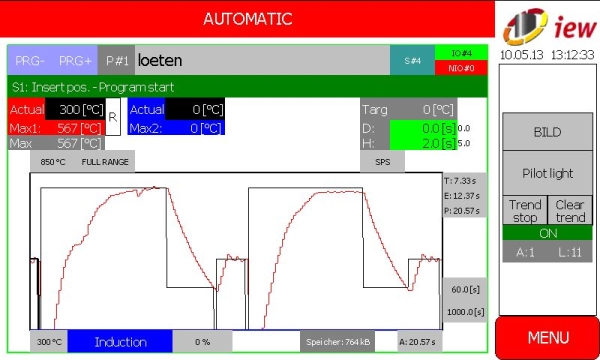

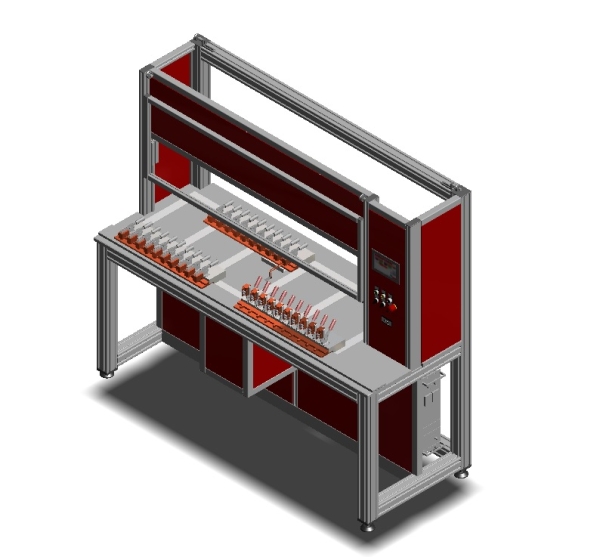

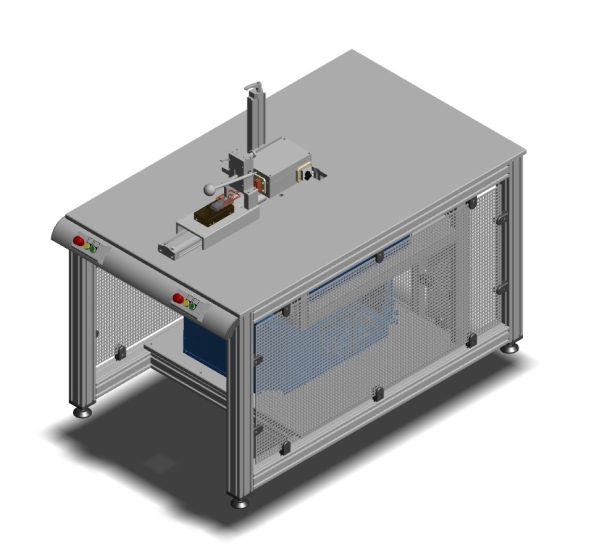

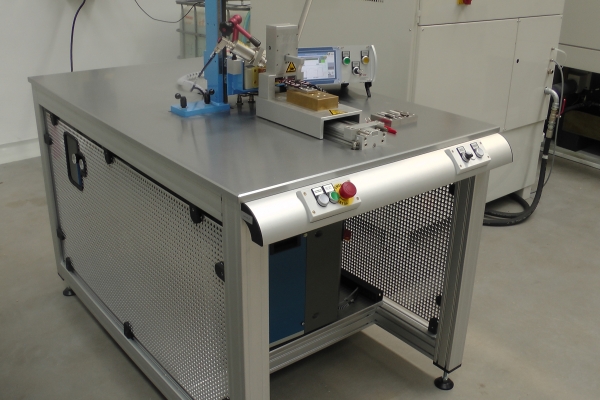

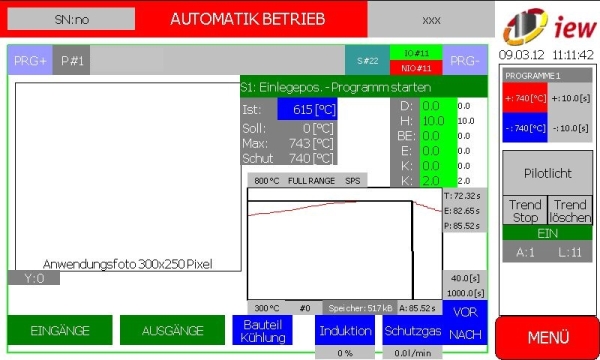

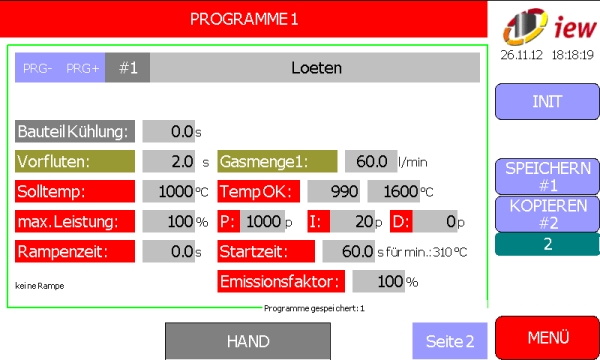

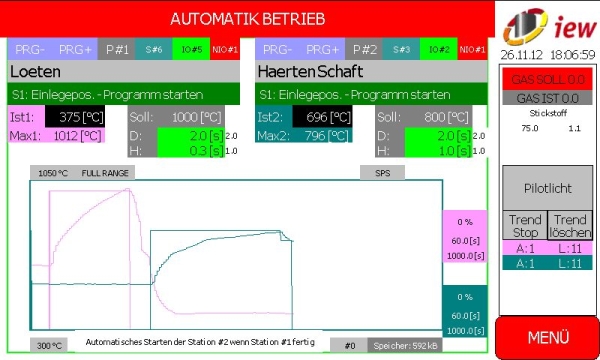

The single components of iew have been integrated locally on a worktable supplied by the customer. The small hardening unit consists of a PLC sequence control (menu guidance in German and English) for the power control of the induction system, the activation of a solenoid valve for the emulsion shower and an infrared pyrometer for the temperature measurement. A drip pan for the emulsion liquid has also been integrated in the working table which is also equipped with a temperature sensor and connection to a cooling system to ensure a constant emulsion temperature.

As the weekly number of hardness components was only about 300pcs but the need to integrate the hardening process into the in-house manufacturing process was given, the more cost effective solution where the induction hardening unit was integrated into an already available worktable at the customer was chosen.