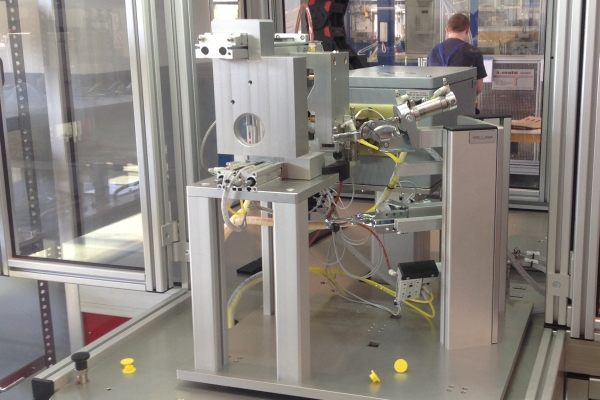

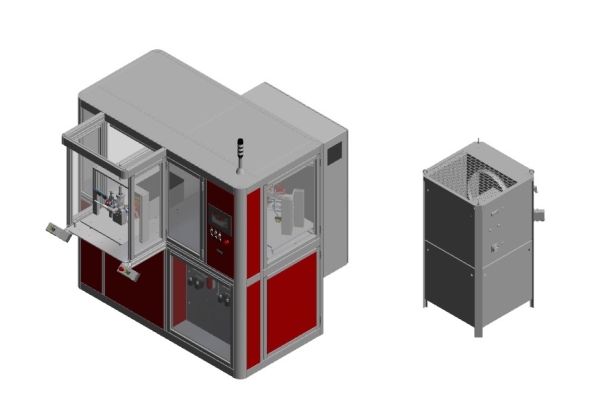

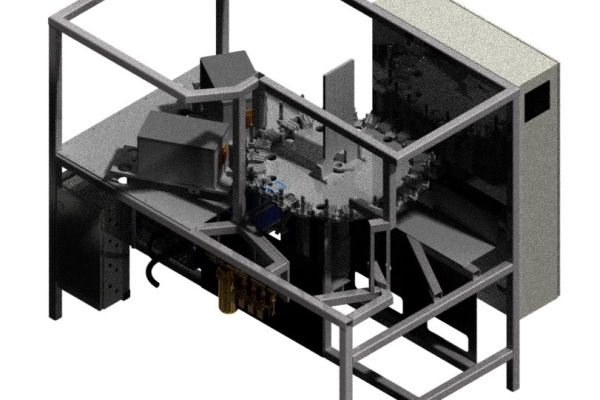

IBU115 (Induction Brazing Unit – 1 x TTH15 15kW)

Lötanlage

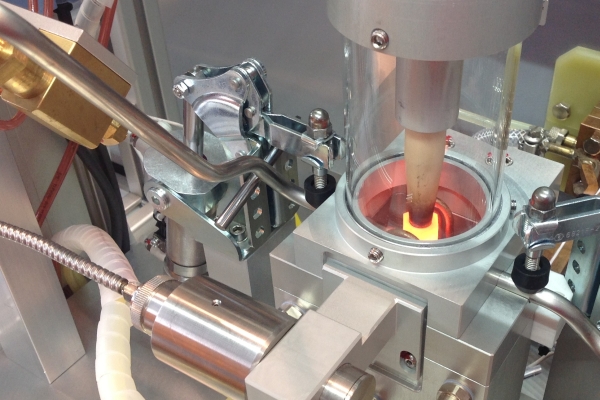

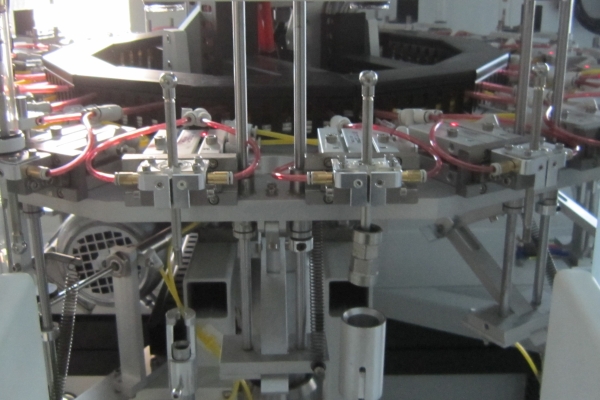

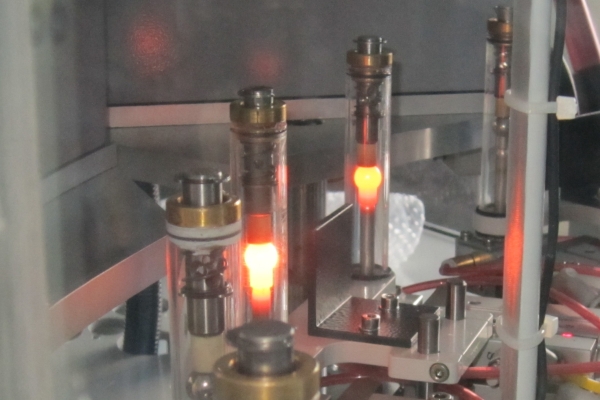

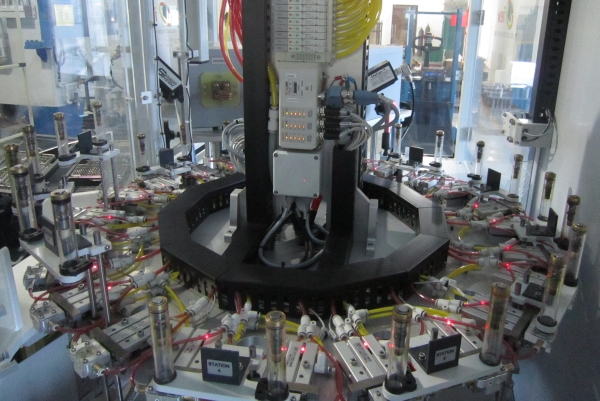

This brazing workplace has been equipped with a protection gas unit and has been designed for the inductive brazing of stainless steel tubes and turned/milled parts in the shape of T- and pipe fittings.

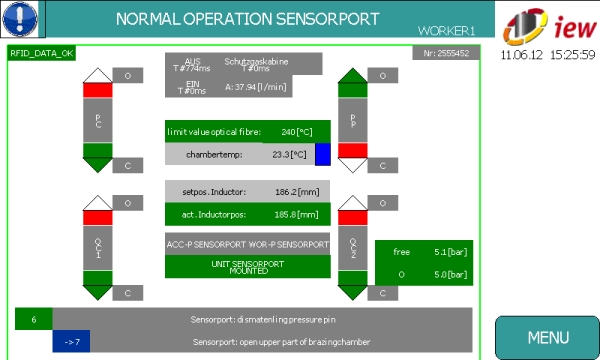

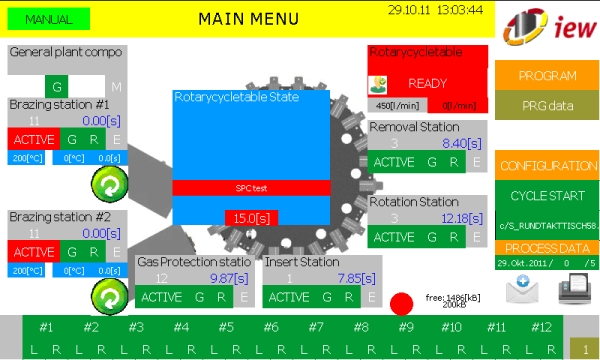

The operator manually inserts the single components and activates a clamping tool via a two hand activator. The brazing assembly naturally comes with a RFID component identification. This ensures that the customer specific brazing program is chosen and all product-dependent parameters regarding the protection gas unit are initialized. Preparation- and type errors can thereby be eliminated. The brazing assembly has been designed for a five-day working week in a three shift working pattern for 30.000 parts a year with 2 brazing joints each. The PLC interface always displays the current brazing process and supervises every single assembly step. Furthermore, the corresponding temperature profile is graphically displayed. The brazing parameters are saved within a loc-file (Name of operator, temperatur profile, maximum temperature, amount of protection gas, etc.).

The device was designed in a way that allows an alteration of the product line. To achieve this, only the customer specific product carries has to be altered. Thereby, the operation of the IBU115 is warranted for years.