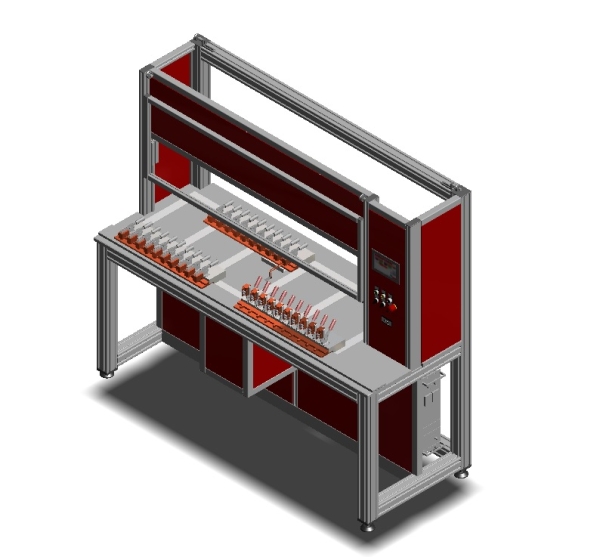

IBU105/3 (Induction Brazing Unit – 1 x TTH5t 5kW)

Lötanlage

This assembly is a semiautomatic brazing workplace for the inductive brazing of saw teeth onto chain links.

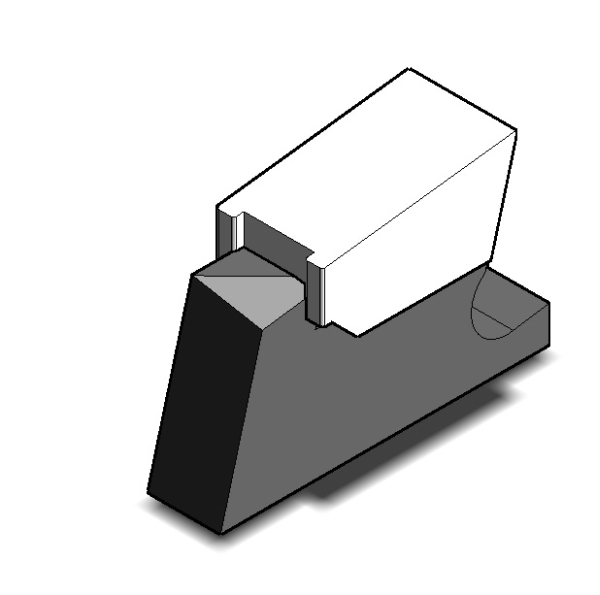

Thereby, a staff member assembles a product carrier with 10 chain links, adds the saw teeth together with the brazing foil and finally fixes them in a retainer jaw. After closing the fixation, the carrier plate is positioned behind a manually lockable safety glass. The following brazing process starts automatically and the 10 brazing joints are clocked one after another, utilitzing a carriage system and an open fork inductor. The completion of the brazing process is followed by an acoustic signal.

The assembly naturally features a PLC as well as a contact-free temperature measuring system (infrared-pyrometer). The carrier plate comes up with an integrated water cooling system to ensure stable brazing conditions.