IHU108 (Induction Hardening Unit – 1 x TTH8 8kW)

Härteanlagen

This hardening unit is used as a part of a training system for determining the energy efficiency of a welding and subsequent hardening process.

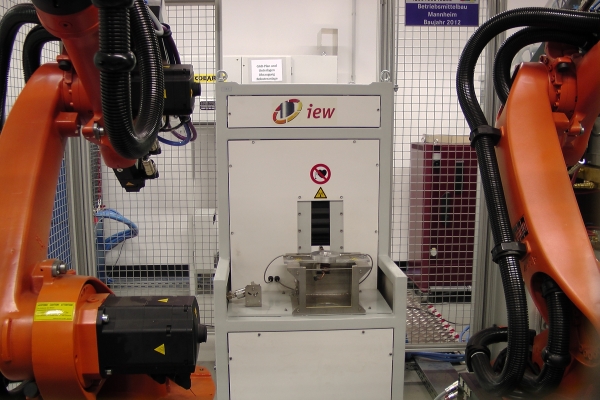

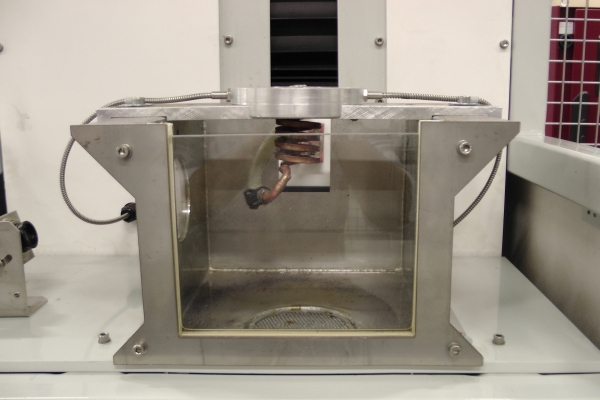

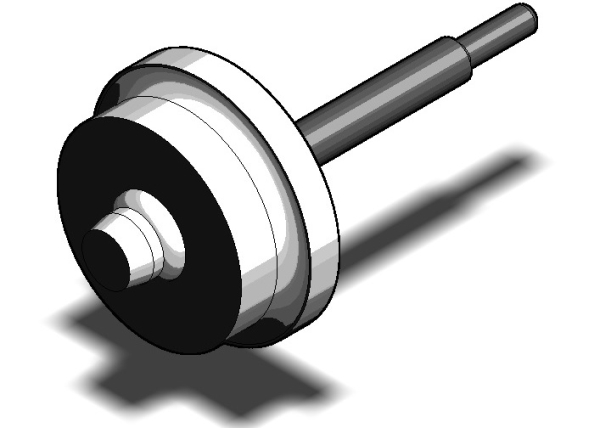

First, the workpiece carrier plate is equipped with a compressor wheel and a shaft and retracted into the security cell by pressing a button. From this carrier plate a robot takes the two parts and clamps them in an automated welding system where they are welded. In the following step, the component is extracted by the robot and inserted into the holding fixture of the IHU108. After an optical workpiece recognition, the actual hardening process starts with a setpoint temperature of 1000 °C. Thereafter, the workpiece is quenched by a shower integrated in the inductor.

Through the PLC sequence control, as well as the contactless temperature measurement (pyrometer) multiple heating programs can be defined which allows the training participants to be gradually introduced to the improvement of the energy efficiency. After removing the finished component from the IHU108 it is again deposited on the carrier plate and then discharged out of the safety cell.