IHU110 (Induction Hardening Unit – 1 x TTH10 10kW)

Härteanlagen

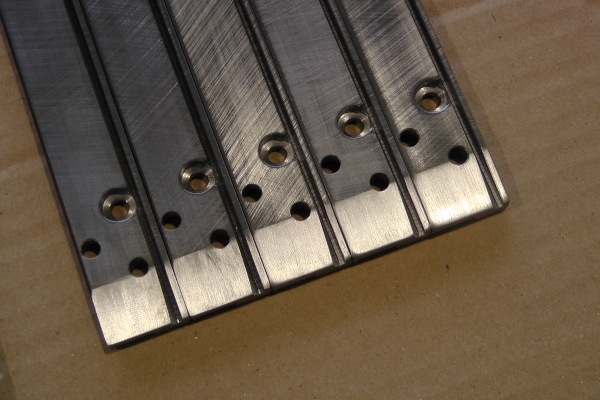

This small workplace was designed for the hardening of roller bars in the textile industry.

Since the customer is also an engineering company, they could make the periphery in form of a cooling bath and workpiece fixture by themselves. During the hardening process, the bar is placed in a fixture and is heated at one of the two front ends. Upon reaching the desired temperature, this front end is quenched and hardened by an emulsion shower. Thereafter, the bar is manually rotated 180 degrees, and the hardening process takes place again on the second front end.

Of course, the hardening unit IHU110 is equipped with an infrared pyrometer and a PLC sequence control (menu guidance in German and English). Additionally it is equipped with two solenoid valves to control the emulsion shower and the component cooling.