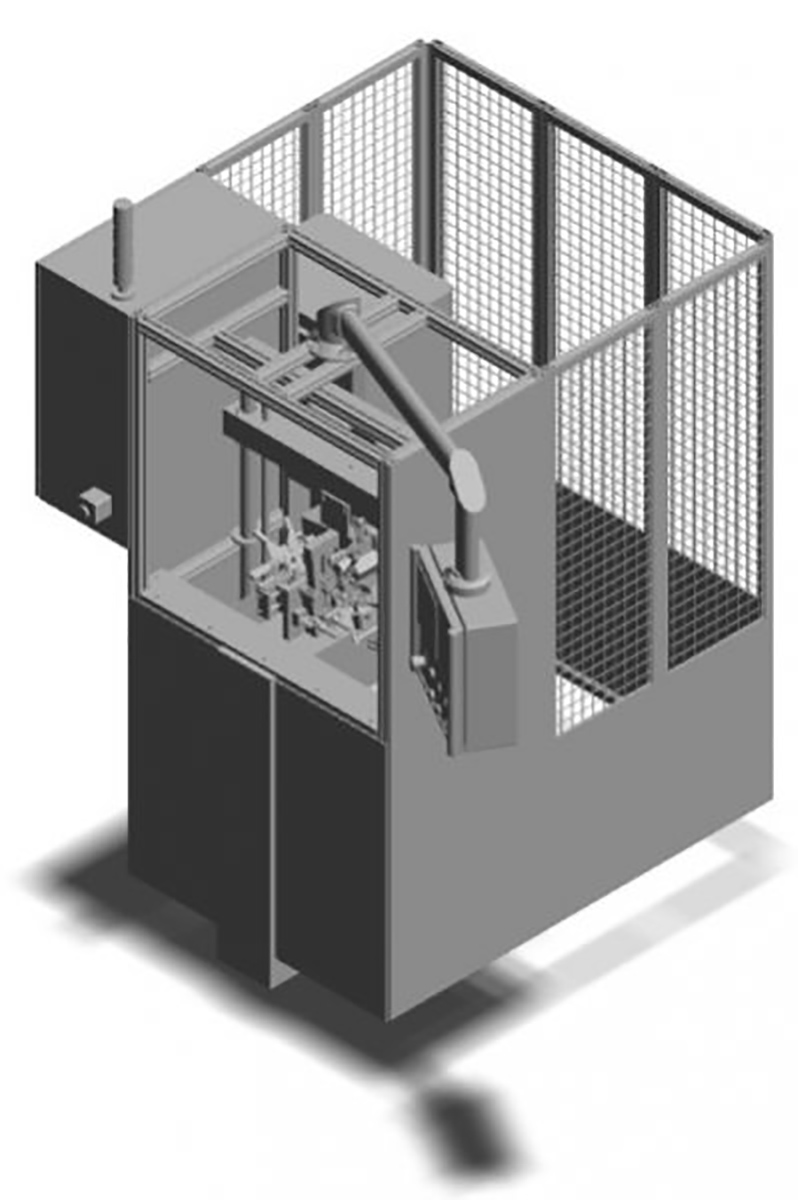

IHU130 (Induction Hardening Unit – 1 x TN30 30kW)

Härteanlagen

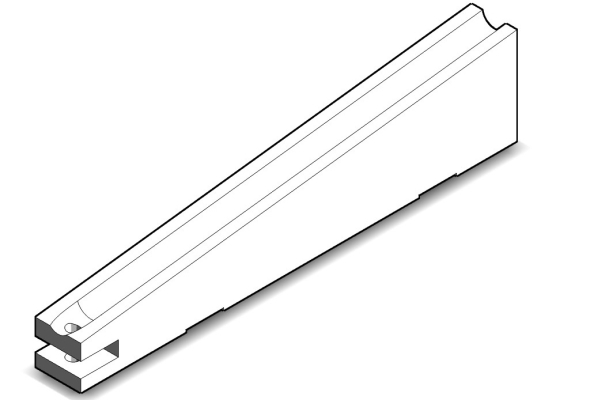

This hardening system was developed for the hardening of elevator components (cable guide and securing clamps) and built for a wage labor hardening plant.

The to be hardened components are clamped into a stationary device and heated to approximately 900 °C. Upon reaching the hardening temperature, the entire device is lowered into the corresponding emulsion bath. In addition, workpieces with a length of up to 300mm can be inductively heated in a continuous process and then quenched in the emulsion bath via feed control. This fastest possible cooling of the components ensures a steady and constant hardness. Due to the complete cooling of the hardening component it can be manually removed from the device without risk of burns. Furthermore, due to the use of an emulsion bath, the use of workpiece related cooling showers is no longer necessary.

In order to ensure a 100% constant hardness degree, the emulsion tank is equipped with a temperature sensor and integrated cooling system.