Inert Gas and Vacuum Technology

Inert Gas and Vacuum Technology

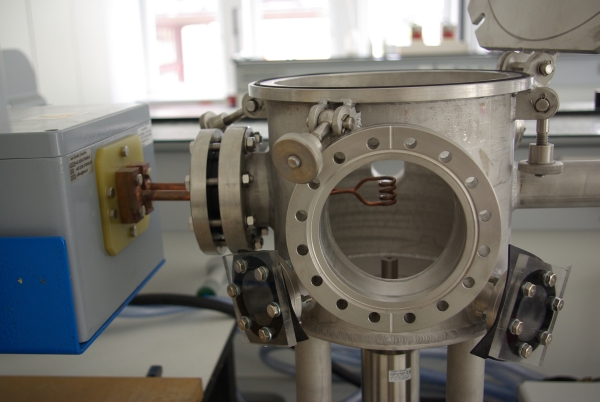

Special materials or specific application areas often require specialized processing methods.

The flux used in conventional brazing processes is frequently the cause of corrosion and burn marks on the workpiece. Inclusions of flux can also impair the mechanical properties of the component. Additionally, the presence of oxygen in the atmosphere can lead to discoloration of the workpiece surface.

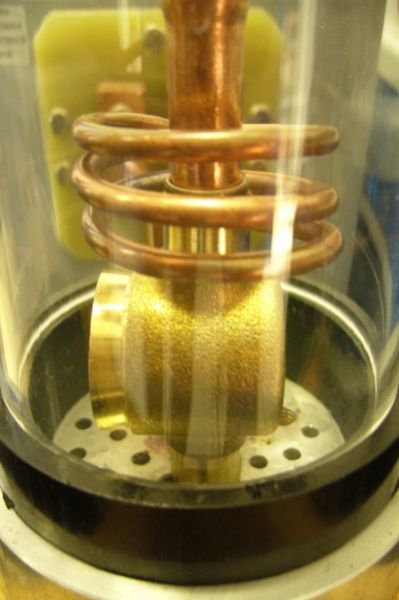

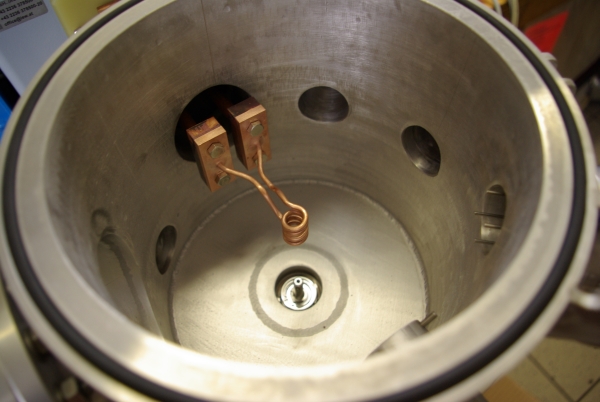

These issues can be effectively avoided by brazing under inert gas or vacuum. The inert gas brazing process is highly compatible with induction heating, as no open flame is present during the process and the gas flow conditions can be precisely controlled.