Tempering

Tempering

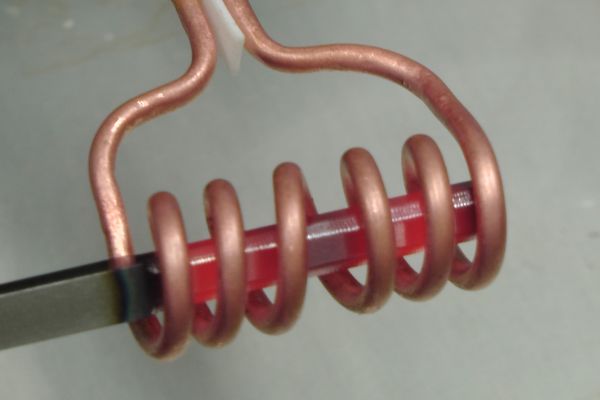

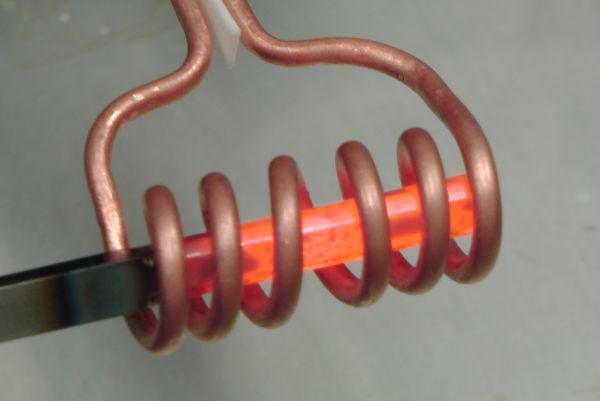

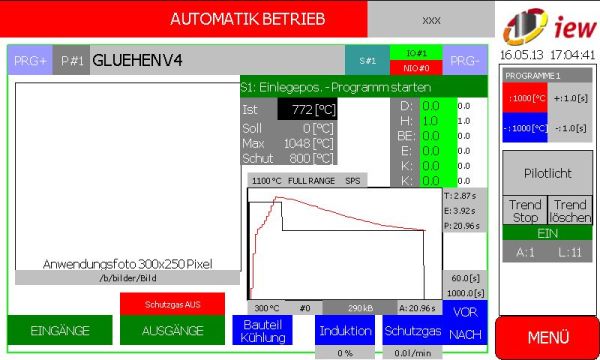

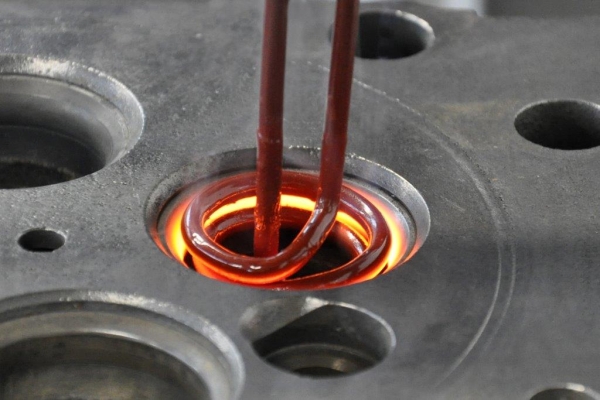

The inductive tempering is a subsection of the heat treatment in which a predefined warm-up, through heating and cooling process leads to specific desired component properties.

The most important case for the induction process are the soft annealing and stress relief annealing:

During soft annealing, the hardness and strength of the steel is reduced in order to facilitate deformation. This typically happens at temperatures between 680 ° C and 780 ° C.

The second typical application is the stress relief annealing which is carried out at the relatively low temperatures of 480 ° C – 680 ° C. Stress relief annealing is used to eliminate residual stresses in the workpiece, which have been induced by mechanical deformation or machining. If possible, the remaining material properties should not be changed.

In this case the induction heating method also provides essential advantages: Both the temperature and the heating time can be accurately determined and adhered to. This ultimately leads to a high reproducibility and consistent part quality.

In the area of the rework of internal combustion engines, the iew GmbH is cooperating with the powerful affiliate KaMaTec.