Brazing and soldering of metals

Brazing and soldering

Induction brazing in practice, soldering, brazing, and high temperature brazing at a glance

Metals can be joined metallurgically by induction heating in combination with brazing alloys or solder alloys. Thanks to the adaptability of induction and modern filler metals, both ferromagnetic and non ferromagnetic materials can be combined and bonded reliably. Our systems support automated and manual brazing, which makes them a robust solution for one off jobs and for series production.

Process overview

We distinguish three joining methods. Selection depends on base materials, temperature window, strength and leak tightness requirements, and part geometry.

Soldering

Soldering takes place below about 450 degrees Celsius. Typical solders are tin based, for example tin copper or tin silver. Heat input is low, parts are protected. Soldering is suitable for electrical joints, housings, thin walled components, and applications with low service temperatures. Clean surfaces, the correct joint gap, and a suitable flux are essential. With induction, heat is delivered precisely to the joint, cycle times stay short, part distortion remains low.

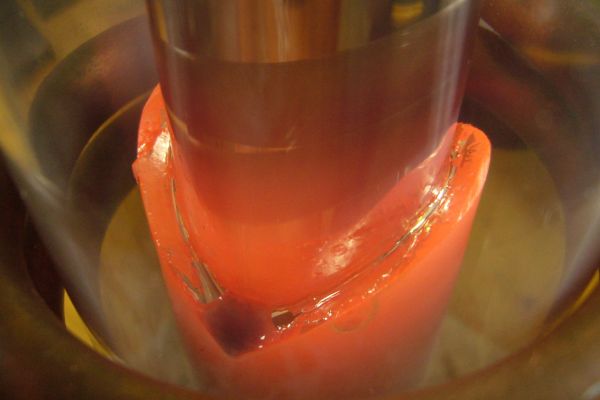

Brazing

Brazing covers about 450 to 900 degrees Celsius. Common filler metals include silver based alloys, copper phosphorus for copper based parts, and specially manganese or nickel alloyed fillers for poorly wetting materials. Brazing is the standard for high strength, leak tight, visually clean joints. Induction allows tight control of joint tolerances and precise process regulation. Capillary action is supported by a gap typically 0.02 to 0.08 millimeters. Time above liquidus is short, often 10 to 60 seconds, depending on mass and coupling.

High temperature brazing

High temperature brazing starts at about 900 degrees Celsius. Typical choices are nickel based fillers, as well as copper or active brazing alloys for ceramics, hard materials, and cemented carbides. The process is preferably run in protection gas or in a vacuum to avoid oxidation and to improve wetting. Induction enables short heat up times and accurate peak temperature control. Surfaces remain clean, post processing is reduced.

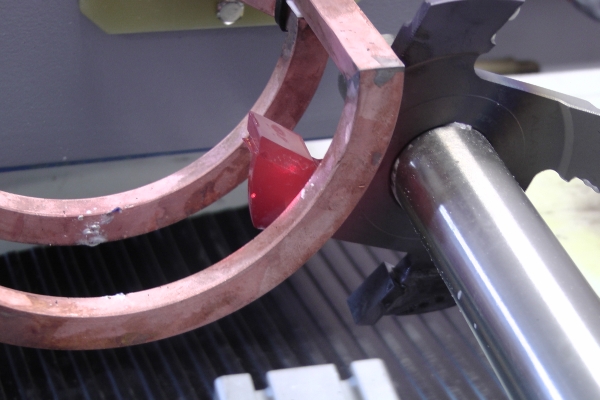

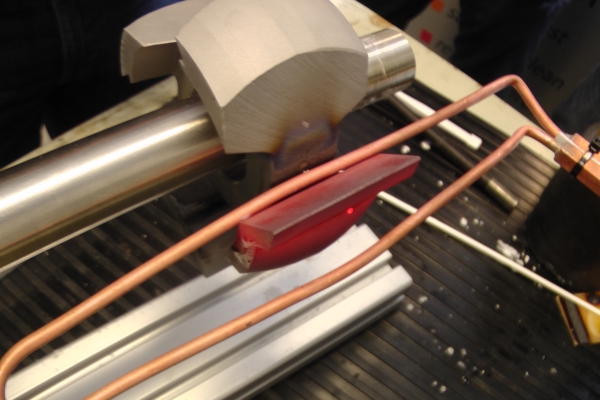

Brazing cemented carbides to steel

Cemented carbides have a high metal carbide fraction, most commonly tungsten carbide. They are brazed to steel carriers to improve tool life and wear resistance. Because carbides can be difficult to wet, silver based fillers with manganese or nickel containing variants are often used. In practice, the following approach has proven effective:

- Keep the joint gap tight, a typical target is 0.02 to 0.05 millimeters, uniform across the entire interface

- Preheat to reduce thermal stress, heat carbide and carrier evenly, limit temperature gradients

- Use preforms, rings or foil to define filler quantity and flow behaviour

- Use flux matched to the alloy, or run the process in protection gas or in vacuum

- Hold briefly above liquidus, then allow a calm cool down to minimize residual stress

With induction the heat input is local, the joint zone heats rapidly and in a controlled manner, distortion and risk of cracking are reduced. Temperature control can be monitored and documented with a pyrometer if required.

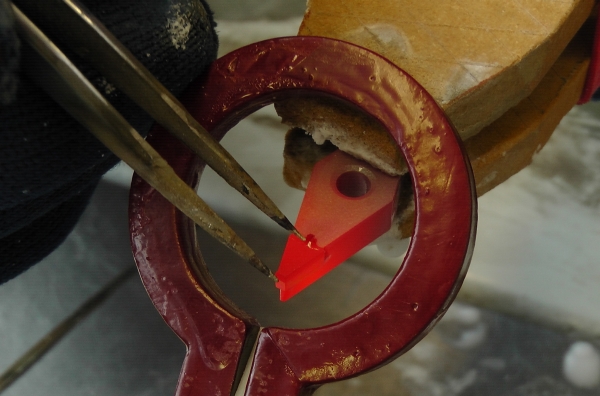

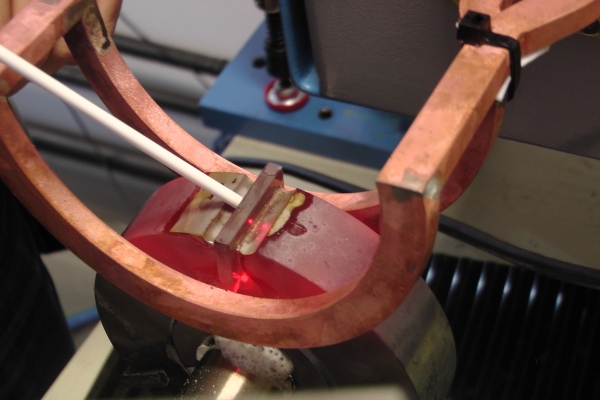

Brazing PCD and PCBN

PCD and PCBN are sensitive to local overheating. Precise temperature control with induction is therefore a clear advantage over flame brazing. The goal is a short, repeatable hold time above liquidus with minimal thermal load on the superhard cutting layer. Proven measures include the following:

- Shape the inductor to concentrate heating on the joint zone, not on the cutting layer

- Use protection gas or vacuum to protect surfaces and support wetting

- Keep the hold time short above liquidus, then cool in a defined way to avoid thermal stress

- Use preforms or foil to keep filler quantity constant and joints clean

Fast, local heating with induction avoids hot spots in the PCD or PCBN layer while keeping the joint in the process window long enough for reliable wetting and high joint strength.

How to plan a stable brazing process

- Define the material pairing, prepare the surfaces, degrease and remove oxides

- Select the filler metal for service temperature, strength, wetting, and media resistance

- Fix the joint geometry, secure capillary flow, ensure flat, well fitting surfaces

- Design the inductor for the part and access, keep the coupling distance constant

- Control the process with regulated power, temperature measurement, and a documented time above liquidus

- Verify quality by visual inspection, macro sectioning, tensile or shear testing, or leak testing

FAQ on induction brazing

What joint gap is ideal

For silver based brazing fillers a typical range is 0.02 to 0.08 millimeters. For copper phosphorus on copper the ranges are similar. Nickel based fillers in high temperature brazing often run at 0.02 to 0.05 millimeters. Uniformity of the gap is critical.

Do I need flux or protection gas

Many applications work well with a suitable flux. For demanding pairings, for cemented carbides, or for sensitive surfaces, protection gas or vacuum is a viable option. The objective is clean surfaces and stable wetting.

How do I avoid cracks when brazing carbide

Limit temperature gradients, preheat, use tight and uniform gaps, keep hold times short, and cool with low stress. A suitable filler composition, for example with manganese, improves wetting.

How do I protect PCD and PCBN from overheating

Focus inductor power on the joint, select a short hold time, and monitor temperature. Preforms or foil keep filler volume constant and joints consistent.

When should I choose high temperature brazing

Choose it for high service temperatures, demanding media resistance, or challenging material pairings. Typical cases include nickel based fillers for highly loaded joints or active fillers for ceramics and hard materials. Protection gas or vacuum is preferred.

Planning an induction brazing process, we support filler selection, inductor design, and process validation until the process runs reliably.