Tempering

Tempering

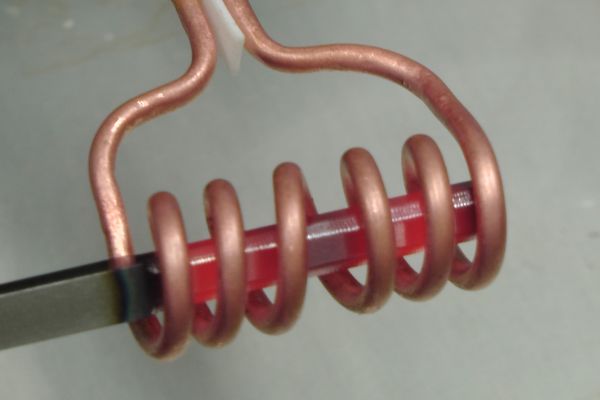

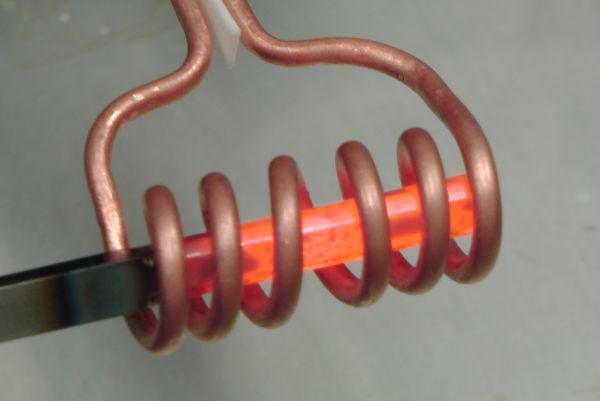

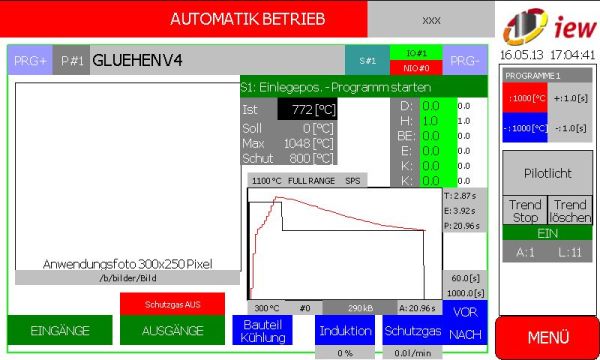

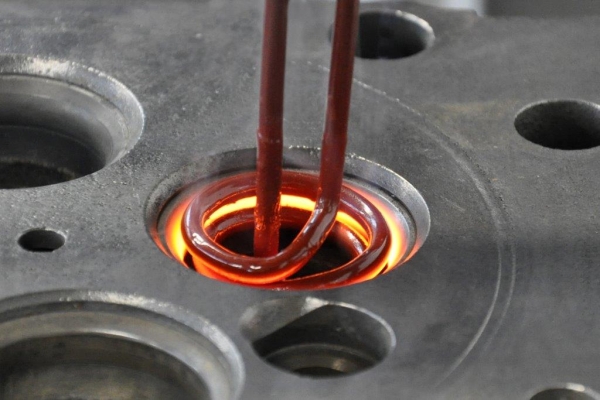

Inductive annealing is a part of heat treatment in which a predefined sequence of heating and cooling steps produces specific desired material properties in the component.

The most important processes in this field are soft annealing and stress relief annealing:

During soft annealing, the hardness and strength of the steel are reduced to facilitate deformation. This process typically takes place at temperatures between 680 °C and 780 °C.

Stress relief annealing, on the other hand, is performed at relatively low temperatures between 480 °C and 680 °C. It is used to eliminate residual stresses in the workpiece caused by mechanical deformation or machining, while maintaining the material’s other properties as much as possible.

The induction heating method offers significant advantages for these applications: both the temperature and the heating time can be precisely controlled and maintained. This ensures high reproducibility and consistently excellent part quality.

In the area of the rework of internal combustion engines, the iew GmbH is cooperating with the powerful affiliate KaMaTec.