Hardening

Hardening

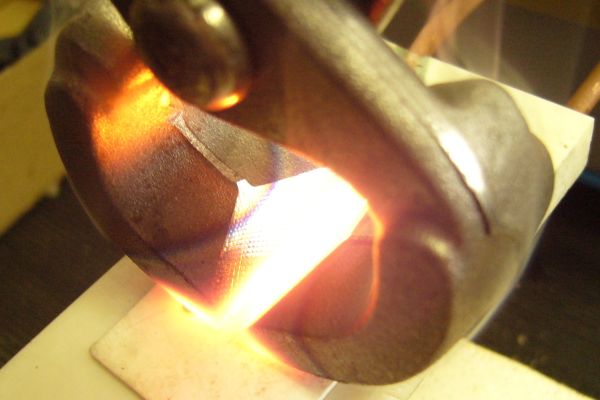

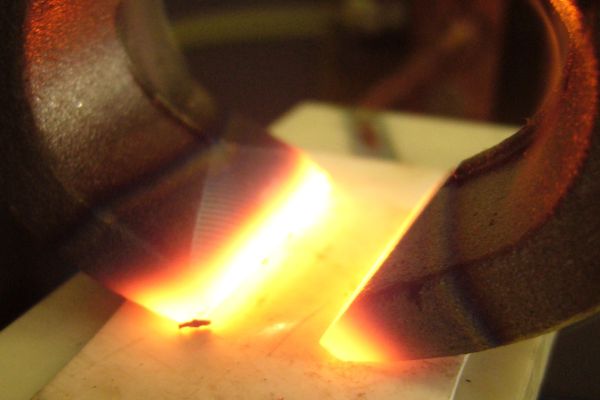

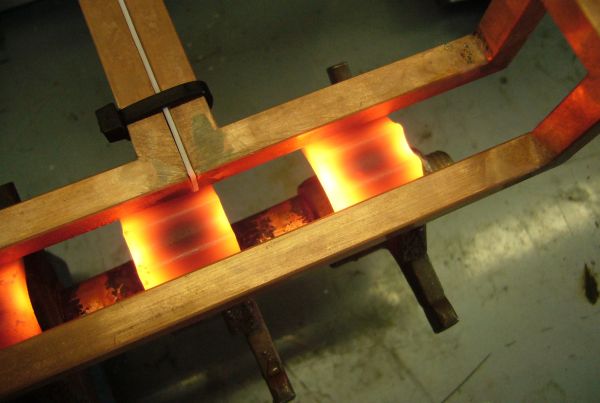

Induction hardening is primarily used for the hardening of bearing surfaces, shafts, and complexly shaped components where only specific areas require heating.

The operating frequency of the induction heating system determines the depth of heat penetration. Depending on the process requirements, the hardened area can be cooled in air, with water, or using a special hardening emulsion. Each cooling medium results in a different degree of hardness.

Induction hardening can be implemented as either a manual or an automated solution, and it can also be integrated into a continuous production process.